Home

Cryogenic Completes Major Expansion of Manufacturing Facility in London, UK

Cryogenic has recently completed a major expansion of its manufacturing capabilities. After experiencing record intake due to Cryogenics’ strong reputation for supplying high quality magnet systems, the investment enhances Cryogenics’ capability to increase product quality, output and so meet market demand.

The expansion, covering new building premises and production equipment, includes doubling its main building foot print, doubling its in-house electronics footprint, building a controlled-environment room, increased coil winding capability and investing in a state of the art in-house machine shop. All together this will increases productivity of our core magnet technology as well as to allow greater capacity for bespoke and high specification magnets to be developed.

News & Events

5T-2T-2T Optical Vector Cryogen-Free Magnet

The OV-CFM system is based on a well-proven modular design incorporating proprietary technology to allow a vector magnet and integrated variable temperature sample space to be operated in a way that allows precise temperature control while varying the magnetic field. The magnet operates dry and no liquid cryogens are required at start up or during operation.

The OV-CFM system is based on a well-proven modular design incorporating proprietary technology to allow a vector magnet and integrated variable temperature sample space to be operated in a way that allows precise temperature control while varying the magnetic field. The magnet operates dry and no liquid cryogens are required at start up or during operation.

The standard system comes with crystalline quartz windows. To work with terahertz radiation, alternative materials are available including Polymethylpentene (TPX) for the outer windows.

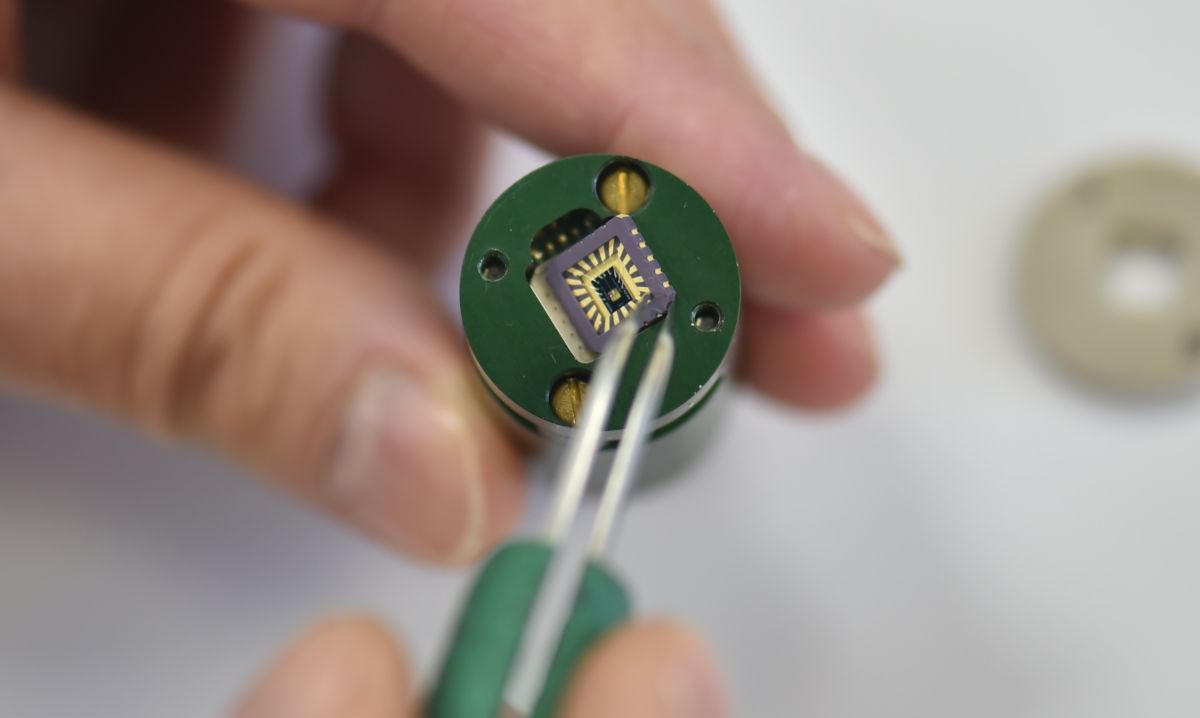

Superconducting vector magnet assembly

1.5 W PT Cold-head and F100 compressor

Scroll pump & 4He gas reservoir for recirculating VTI operation

50 mm (49mm clear) Variable Temperature Space

Gate valve to isolate VTI space